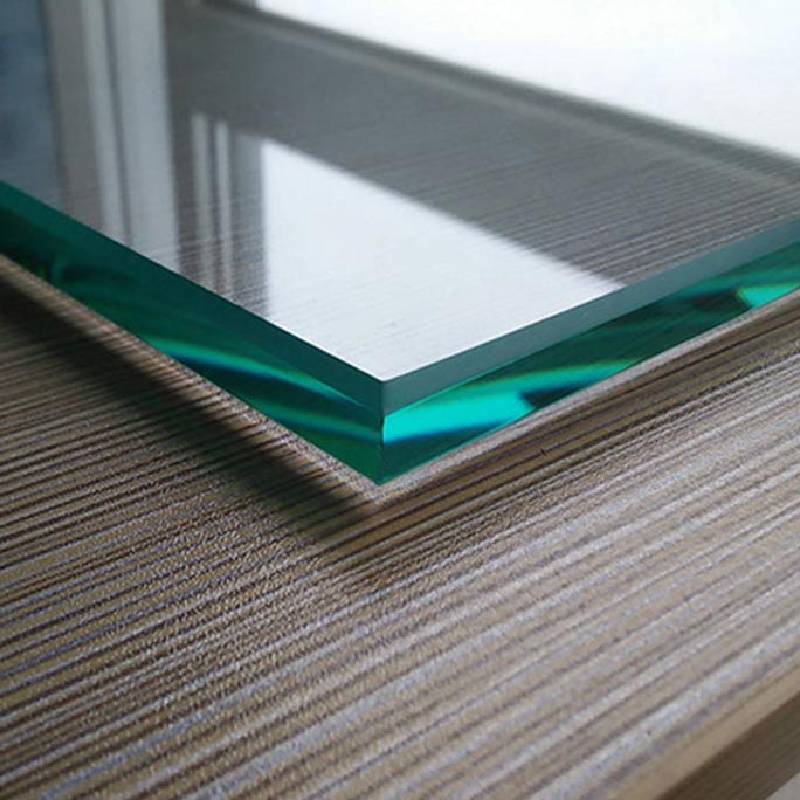

In an article in the Atlantic, glass was called humanity's most important material. In order to connect you and me, writes Douglas Main, these words are encoded into optical signals that travel at 300, 000 kilometers per second through fiber-optic cables, across mountains, underwater, across cities and countries, and across the globe. The glass inside these cables is thinner than a human hair and 30 times more transparent than the purest water. Glass allows us to see and be seen, to hear and be heard, to light up our rooms, our lives and our thoughts.

Home

Home

It's common to see such mirrors in various shapes and sizes, from sprawling, floor-to-ceiling designs that create the illusion of spaciousness to petite, circular pieces that serve as decorative accents It's common to see such mirrors in various shapes and sizes, from sprawling, floor-to-ceiling designs that create the illusion of spaciousness to petite, circular pieces that serve as decorative accents

It's common to see such mirrors in various shapes and sizes, from sprawling, floor-to-ceiling designs that create the illusion of spaciousness to petite, circular pieces that serve as decorative accents It's common to see such mirrors in various shapes and sizes, from sprawling, floor-to-ceiling designs that create the illusion of spaciousness to petite, circular pieces that serve as decorative accents

It is present in the grand ballrooms where it reflects the extravagance of galas and in the humble bedrooms where it witnesses the daily rituals of ordinary people It is present in the grand ballrooms where it reflects the extravagance of galas and in the humble bedrooms where it witnesses the daily rituals of ordinary people

It is present in the grand ballrooms where it reflects the extravagance of galas and in the humble bedrooms where it witnesses the daily rituals of ordinary people It is present in the grand ballrooms where it reflects the extravagance of galas and in the humble bedrooms where it witnesses the daily rituals of ordinary people

This safety feature makes it an indispensable component in architectural designs, particularly for windows, doors, shower enclosures, and even in vehicle manufacturing This safety feature makes it an indispensable component in architectural designs, particularly for windows, doors, shower enclosures, and even in vehicle manufacturing

This safety feature makes it an indispensable component in architectural designs, particularly for windows, doors, shower enclosures, and even in vehicle manufacturing This safety feature makes it an indispensable component in architectural designs, particularly for windows, doors, shower enclosures, and even in vehicle manufacturing

They also provide technical support, ensuring seamless integration of these solutions into the manufacturing process They also provide technical support, ensuring seamless integration of these solutions into the manufacturing process

They also provide technical support, ensuring seamless integration of these solutions into the manufacturing process They also provide technical support, ensuring seamless integration of these solutions into the manufacturing process